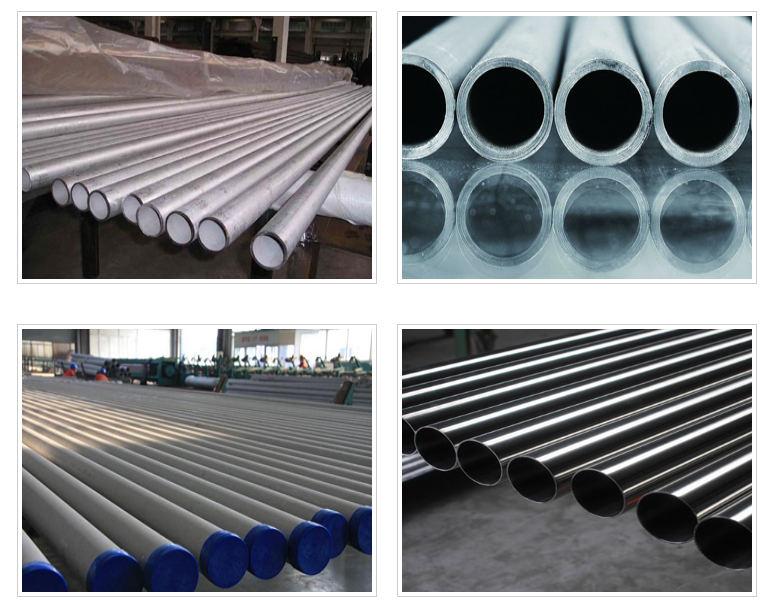

Stainless steel seamless pipe is a long steel with a hollow section and no joints around. The thicker the wall thickness of the product, the more economical and practical, the thinner the wall thickness, the greater the processing cost. The technology of the product determines its limited performance. Generally, stainless steel seamless pipes have low precision: uneven wall thickness, low brightness inside and outside the pipe, high length cost, and pits and black spots that are not easy to remove inside and outside the pipe; its detection and shaping must be processed offline. Therefore, it shows superiority in high pressure, high strength and mechanical structural materials.

From the point of view of manufacturing process: stainless steel seamless pipe is made of steel rod through perforation technology and rolling technology; stainless steel welded pipe is made of strip stainless steel plate, rolled into a tube shape, and welded at the joint (usually argon arc welding and plasma welding are used) ). From the point of view of use: seamless pipes are used in places with high pressure, and welded pipes are used in places with low pressure or as structural pipes. For example, stainless steel pipes for furniture and decoration are all welded.

There are many kinds of stainless steel seamless pipes, one of which is a strip with a hollow section and no joints around. The thicker the wall thickness of the stainless steel seamless pipe, the more economical and practical, the thinner the wall thickness, the higher the processing cost. The technology of the product determines its limited performance. Generally, stainless steel seamless pipes have low precision: uneven wall thickness, low brightness inside and outside the pipe, high length cost, and pits and black spots that are not easy to remove inside and outside the pipe; its detection and shaping must be processed offline. Therefore, it shows superiority in high pressure, high strength and mechanical structural materials.

Stainless steel fluid pipes are safe, reliable, hygienic, environmentally friendly, and economical. The thin-walledness of the pipe and the successful development of a new reliable, simple and convenient connection method make it more irreplaceable for other pipes. Its application in engineering will become more and more, and its use will become more and more popular.

With the development of economy, the use of stainless steel seamless pipes is becoming more and more extensive. People are closely related to stainless steel in their daily life, but many people do not know much about the performance of stainless steel, and there is little maintenance of stainless steel seamless pipes.

Many people think that stainless steel does not rust. In fact, stainless steel has good corrosion resistance. The reason is that a passivation film is formed on the surface, which is essentially in the form of a more stable oxide. That is to say, although stainless steel has different degrees of oxidation depending on the conditions of use, it will eventually be oxidized, which is usually called corrosion.

All metal surfaces exposed to corrosive environments undergo electrochemical or chemical reactions and are uniformly corroded. In the passivation film on the surface of the stainless steel seamless pipe, pitting corrosion is formed due to the self-excited reaction, and small holes are formed. In addition, chloride ions are close to form a strong corrosive solution, which accelerates the corrosion reaction.

There are also intergranular corrosion cracks in stainless steel, which destroy the passive film on the surface of the stainless steel plate. Therefore, stainless steel surfaces must be cleaned and maintained regularly to maintain a gorgeous finish and extend their life.

Stainless steel seamless pipe is one of the best comprehensive performance, new energy-saving and environmentally friendly pipes in the water supply system, and it is also a very competitive water supply pipe, which will play an unparalleled role in improving water quality and people's living standards. From the point of view of manufacturing process: stainless steel seamless pipe is made of steel rod through perforation technology and rolling technology; stainless steel welded pipe is made of strip stainless steel plate, rolled into a tube shape, and welded at the joint (usually argon arc welding and plasma welding are used) ). From the point of view of use: seamless pipes are used in places with high pressure, and welded pipes are used in places with low pressure or as structural pipes. For example, stainless steel pipes for furniture and decoration are all welded.

There is no welding gap around the stainless steel seamless pipe. It is called seamless stainless steel pipe because it is made of stainless steel pipe with good high temperature resistance and corrosion resistance. Seamless stainless steel pipes are usually used for seamless stainless steel pipes of ordinary structures and mechanical structures.

For example, hot rolling/cold rolling of various stainless steels, pipes for chemical and petroleum equipment, and stainless steel structural components for various purposes. Since the hollow at both ends of the stainless steel seamless pipe is usually circular, the area of the circular end of the seamless stainless steel pipe is the largest when the circumference is the same. In life practice, round tubes are usually used to transport liquids. We refer to the steel pipe that transports water, oil and other liquids as fluid transport seamless steel pipe.

Stainless steel seamless pipes and round pipes will definitely have certain limitations in use. If bent under pressure, round pipes have better compression and bending resistance than square or rectangular pipes, so different seamless stainless steel pipes are manufactured according to different functions and uses.

Post time: Jun-27-2022